What are the advantages of Laser Marking

PV:341

Laser engraving, which is a subset of laser marking is the practice of using lasers to engrave an object. Laser marking, on the other hand, is a broader category of methods to leave marks on an object, which also includes color change due to chemical/molecular alteration, charring, foaming, melting, ablation, and more. The technique does not involve the use of inks, nor does it involve tool bits which contact the engraving surface and wear out, giving it an advantage over alternative engraving or marking technologies where inks or bit heads have to be replaced regularly.

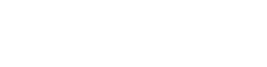

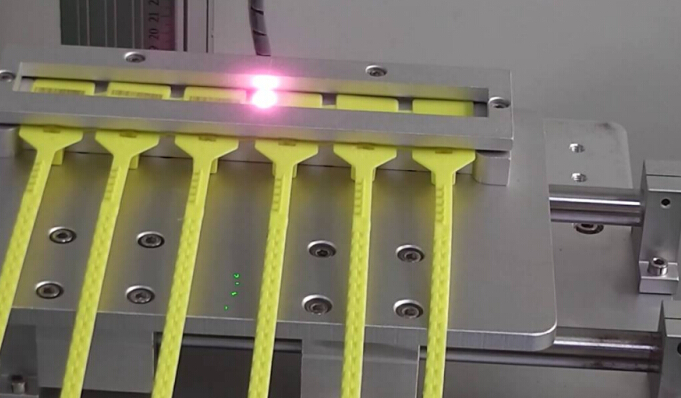

The impact of laser marking has been more pronounced for specially designed “laserable” materials and also for some paints. These include laser-sensitive polymers and novel metal alloys. Plastic security seals have a special aditive impregnated in material which is sensistive to length wave of laser.

Our skilled professionals make use of the latest laser marking tools and techniques to execute these services in an excellent manner. These services are carried out to mark aluminium plates for putting barcode, brand, item number, etc.

Permanency – Unlike other forms of marking, Laser Markings do not degrade due to environmental factors such as contact with Acid, Alkaline, and Gas. Laser marking cannot be affected by changes in temperature. This makes laser marking on security seals ideal for the chemical, pharmaceutical and foods industry. Anti-Counterfeiting – The markings created by the method of laser marking cannot be forged or changed due to its marking technology; thus providing the ultimate tamper evidence for any security seal.

High Processing efficiency – Due to the ability of increasing and decreasing of laser power, the marking strength can be changed to ensure the ideal strength is used for each material. High engraving precision – The articles engraved by laser marker are in fine and elegant patterns and the width of the smallest line can reach 0.04mm, with clear, lasting and elegant marking. Laser marking can satisfy the demand of printing plenty of data on very small plastic object, for instance, two-dimensional code with more precise requirements and higher definition. Due to its unique features and advantages laser marking is the ideal form of marking for all security seals used within the Chemical, Pharmaceuticals and Foods industry. With all three industries carrying substances which can be of acidic nature the laser marking provides the perfect solution with security and strong marking on seals.

clients an excellent quality range of Security Seal Laser Engraving Services . We are able to fabricate best laser cut parts; this service is executed by our experts in accordance with the set standard of market. Our service is high on demand among customers owing to its attractive look & finishing. We are giving this service at competitive price with customized designs options.